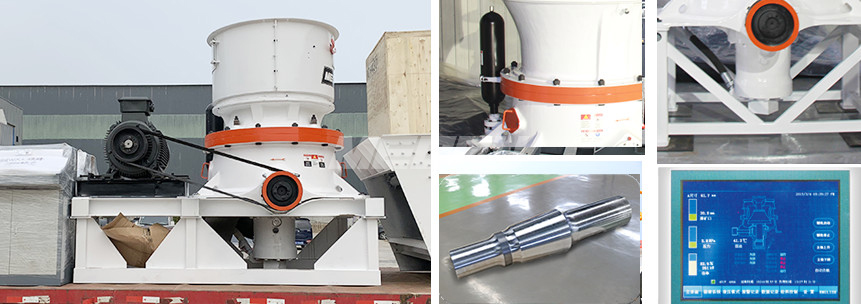

Product Introduction:

Mechanical, hydraulic and intelligent control are integrated, Mecru single-cylinder hydraulic cone crusher adopts new design concepts and technology. The crusher has a hydraulic lifting cone, which can directly complete the discharge opening adjustment, iron pass protection, clear cavity protection, overload protection and other functions during production. Compared with the same type of machine, its crushing ratio is larger, the efficiency is higher, and the finished material produced is uniform in particle size. It is widely used in various sand and gravel crushing and industrial fields.Product Advantages:

1. Mechanical, hydraulic and intelligent control are integrated, the operation is simple and convenient, and the discharge port is adjusted by one button. 2. One machine can change different crushing cavity types. The machine is equipped with multiple medium crushing and fine crushing cavities. Only a few parts such as the corresponding cavity type lining board need to be replaced to convert the machine cavity type. 3. It has a fully automatic production control system, which is convenient and quick to operate and easy for employees to operate. 4. The finished material produced has uniform particle size, and the finished sand and gravel aggregate has excellent quality and good particle shape. 5. The structure of the equipment is relatively simple, which is more convenient for later maintenance and inspection, and greatly reduces the maintenance time.

Working Principle:

The horizontal shaft is driven by the motor to rotate, and the horizontal shaft is driven by the gear to rotate the eccentric shaft, and then the eccentric sleeve drives the moving cone to make a circular swing, so as to realize continuous crushing and crushing of materials. By adjusting the hydraulic cylinder at the bottom of the movable cone, the movable cone can move up and down so as to conveniently adjust the size of the discharge port.Product Parameters:

Technical parameters of single-cylinder cone crusher| model | Cavity type | (mm)Max inlet size | (mm)Min outlet size | (kw)Max power |

| CSG420 | S1(extra coarse) | 240 | 22 | 90 |

| S2(medium coarse) | 200 | 19 | ||

| CHG420 | H1(fine) | 135 | 10 | |

| H2(medium fine ) | 65 | 8 | ||

| H3(extra fine) | 38 | 4 | ||

| CSG430 | S1(extra coarse) | 360 | 25 | 160 |

| S2(medium coarse) | 300 | 22 | ||

| S3(coarse) | 235 | 19 | ||

| CHG430 | H1(fine) | 185 | 13 | |

| H2(medium fine ) | 90 | 10 | ||

| H3(extra fine) | 50 | 6 | ||

| CSG440 | S1(extra coarse) | 450 | 35 | 250 |

| S2(medium coarse) | 400 | 29 | ||

| S3(coarse) | 300 | 25 | ||

| CHG440 | H1(fine) | 215 | 16 | |

| H2(medium fine ) | 110 | 13 | ||

| H3(extra fine) | 70 | 8 | ||

| CSG660 | S1(extra coarse) | 560 | 41 | 315 |

| S2(medium coarse) | 500 | 38 | ||

| CHG660 | H1(fine) | 275 | 16 | |

| H2(medium fine ) | 135 | 16 | ||

| H3(extra fine) | 65 | 13 | ||

| CHG870 | H1(fine) | 300 | 22 | 520 |

| H2(medium fine ) | 155 | 19 | ||

| H3(extra fine) | 80 | 10 | ||

| CHG890 | H1(fine) | 370 | 25 | 750 |

| H2(medium fine ) | 195 | 22 | ||

| H3(extra fine) | 85 | 10 |